Poster: A snowHead

|

|

I have never seen any mention of the bases to be shiny ...mine never are ...more like silk finish after you brush the excess wax off.

|

|

|

|

|

|

Obviously A snowHead isn't a real person

Obviously A snowHead isn't a real person

|

@peter_h, I am not a qualified ski tech, and I normally do boards not skis.

I have not done graphite / sintered bases either, but plenty of good ole P-tex ones.

How I do it might not be the correct or expert way, but seems to work just fine.

If the surface texture is poor, it might mean that the new wax you are applying is going on top of impurities or old wax.

This is what works for me to get a nice shine.

I use citrus based wax remover to give it a good clean first.

After the base cleaner, I run my hand over the base and feel for high spots like micro-burrs of Ptex, and gently remove these.

( Assuming there are no gouges that need filling)

I then wax and leave it for about 45 minutes.

After waxing, I keep scraping until I start to see shiny strips appearing.

Then alternate the (firm) nylon brush and scraper until it has a uniform ( but not super shiny ) glaze.

Then I brush it a dozen or so times with a soft brush, and this brings out a nice shine.

The nylon bush one is a proper ski / board brush by ToKo, but the soft one I finish it with is just a normal boot brush that I use to put a parade sheen on my DMs after I have done polishing them.

To be honest, I think the mirror shine is a bit of gilding the lily, as we normally just ride about in the off piste, under lifts, do piste-side jibs, muck about in the parks, and play on the boarder-x; none of which really requires a super-shiny base, but it's pretty satisfying to achieve it ( and it legitimises extended periods in my man-cave  ) )

|

|

|

|

|

|

Well, the person's real but it's just a made up name, see?

Well, the person's real but it's just a made up name, see?

|

Many thanks.

I did more or less that. Rubbed them down with the brass brush, did the wax (3x over with the iron and it looked fine), then scraped it with the perspex piece (which BTW is useless after that), then nylon brush, then horsehair brush.

It looks like a satin finish.

What I didn't do was the alcohol bit to remove old wax. None was evident to start with.

|

|

|

|

|

|

You need to Login to know who's really who.

You need to Login to know who's really who.

|

Interesting you say that the scraper is now useless.

The perspex scrapers can quickly become covered in wax, which impinges upon their performance.

It might be a bit anal, but I clean the edge every 1 or 2 scrapes to make sure that the surface I am presenting to the board is level, and does not have any small wax residue on it which might stop it from scraping evenly.

I use quite a thick scraper that does not flex, and I endeavour to apply even-ish pressure along its length.

Some of the thinner scrapers can bend into a slight arc if you apply uneven pressure, which can create "ruts" in the wax layer.

I use a soft microfibre cloth when I apply the base cleaner at the start of the process, and use the same cloth to clean perspex scraper too.

You can do courses in base prep, so it might be interesting to take your (non-shiny) skis along and do a one day course.

You could have the teacher demonstrate on one of your skis and you do the other to see what degree of shine is achievable.

Or you could just settle for "silky-enough" as I am sure that'y what 90% of other people do

|

|

|

|

|

|

Anyway, snowHeads is much more fun if you do.

Anyway, snowHeads is much more fun if you do.

|

Watching the YT videos, one is supposed to use the perspex scraper until it is not producing any more shavings.

So it being able to flex seems a good thing.

According to the videos, you are not actually leaving a layer of wax on the ski. Especially after using the nylon brush as shown i.e. until it is producing no more wax dust.

Also my skis don't have a straight bottom all the way along. It is straight in the middle 90-95% or so and at the two endsit is slightly concave, by about 0.5mm. That also means the iron cannot be just simply pulled along like the videos show; one has to rotate it a bit to get it to melt the wax properly at the ends of the ski.

|

|

|

|

|

|

You'll need to Register first of course.

You'll need to Register first of course.

|

| peter_h wrote: |

Many thanks.

I did more or less that. Rubbed them down with the brass brush, did the wax (3x over with the iron and it looked fine), then scraped it with the perspex piece (which BTW is useless after that), then nylon brush, then horsehair brush.

It looks like a satin finish.

What I didn't do was the alcohol bit to remove old wax. None was evident to start with. |

Sounds like you did more than enough. You can get really anal about tuning which is fine but most of us aren't racing. I just wax, cold scrape, once over with a metal brush (I just use a BBQ tool) then buff with a fibretex pad. Base is left sorta shiny but not really mirror reflective

|

|

|

|

|

|

|

|

|

I just wonder where the was really remains... especially after the nylon brush bit. What one sees is the plastic base of the ski, mostly.

|

|

|

|

|

|

|

|

The heat from your iron opens up the base structure so the molten wax can impregnate the sintered base pores .

Heat is the key, the right heat !

Its the reason I bought a 1000w iron as it heats up snowboard noses which are over a foot wide right thru to the top sheet along the whole board lenght .Even in cold resort rooms its still very good .

The 800w irons are not as good on big fat decks and the 400w dakine toys seem a waste of money although probably better than nothing .The house irons are bad news they can melt the pores structure closed in a cold room unseen to the eye.

Which I have done with a house iron in cold uncontrolled room temps where if you do it badly enough the base will change a shade in colour which then requires a base grind

The whole thing is about getting wax deep in the base and is why hot boxes exist for those more serious about it all

All the polishing carry on is secondary if you have time .

I dont bother because in resort a workbench and workshop are a luxary in my case.

Last edited by After all it is free  on Thu 6-12-18 11:55; edited 3 times in total on Thu 6-12-18 11:55; edited 3 times in total

|

|

|

|

|

|

You'll get to see more forums and be part of the best ski club on the net.

You'll get to see more forums and be part of the best ski club on the net.

|

@peter_h, that part about the end of your skis being concave, to me seem a problem.

I'm more than happy to be corrected on it, but I've never owned or serviced skis on which that characteristic I would believe to be correct.

It looks like it would make them very squirrelly to me, ie darting all too aggressively on turn initiation.

Unless someone can indicate to their contrary, I'd feel they need a base grind to make them "flat" from end to end.

If that's the case (linking to your other thread with video) I could understand some of your description of how you feel when skiing along with terrain preference.

It should give a very nervous unpredictable ski set like that, this would make it difficult to progress in skiing skills as a natural nervousness of their reaction would be understandable.

They'd also be really "hooky" ( they seem to have a mind of their own) when used on bumps, which does follow your desire to just ski flat pistes.

|

|

|

|

|

|

|

|

|

yes if you live in resort.

|

|

|

|

|

|

snowHeads are a friendly bunch.

snowHeads are a friendly bunch.

|

| Quote: |

@peter_h, that part about the end of your skis being concave, to me seem a problem.

I'm more than happy to be corrected on it, but I've never owned or serviced skis on which that characteristic I would believe to be correct.

It looks like it would make them very squirrelly to me, ie darting all too aggressively on turn initiation.

|

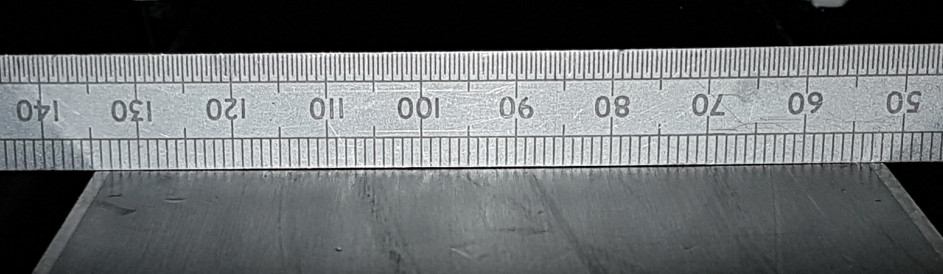

I've done some measurements.

The front 30cm and the back 30cm of each ski is concave, with a gap (against a straight edge) of 0.5-1.0mm. The remaining (middle) part of each ski is flat, to better than 0.2mm. Both skis are identical.

I reckon it is a deliberate manufacturing choice.

These are the Salomon X-Drive 8,0 BT 15/16, bought late 2015.

|

|

|

|

|

|

And love to help out and answer questions and of course, read each other's snow reports.

And love to help out and answer questions and of course, read each other's snow reports.

|

Something very strange there.

Basic principle is for the ski to run on its base only when on a flat plane, the edges are usually kicked up from the flat base by about 0.5degree, generally, to keep them from interacting with the snow. They make contact as you start to lean the ski over in whichever direction you choose. Going for one edge takes the opposite one out of the equation.

Having in effect, hollow, base geometry places both edges into the snow at the same time, making the ski try to steer both ways all else being equal. Any change presented to the ski from ground angle will just drive the ski in whichever direction is strongest, against the intent of the skier.

Maybe someone else will offer an opinion to clarify, but it appears they need base grinding to me.

|

|

|

|

|

|

|

|

The metal edges are flush with the black "plastic" base material. They are not raised up from the base.

IOW, when I hold a (precision steel) ruler against the base of the ski, the ruler touches all the way from one metal edge to the other metal edge. Except at the two ends of the ski, as described above.

I know nuffing about this but would be amazed if that 0.5-1.0mm gap at the ends of the ski made any difference. Snow is compressible... well except some I have skied on, solid frozen stuff which I could not stick the pole into more than 1cm.

|

|

|

|

|

|

You know it makes sense.

|

It's my description that's giving the wrong view I think.

When a ski base is ground, it's flat right the way across from one edge to the other. Only then do the edges get a changed angle (this is where I used "kicked up " wrongly). The angle of the edges are now raised away from the snow by ordinarily 0.5degree up from flat.

Different manufactures will have different specs which are for example quoted as 0.5/1.5 degree which would mean the edge are raised by half degree angle from base, plus the vertical side of the ski edge leans in by one and a half degrees.

The base to edge angle is critical to ski setup and performance. When you lay a steel rule on the base it should be flat all the way across, right along the ski. You should see the half degree angle of the edge geometry visible just under the outer edges of the rule.

That half to one millimeter gap will absolutely affect the ski, it shouldn't be like that.

The ski should run with tge edges slightly lifted out of the snow, yours are doing the opposite, edges in the snow with base lifted.

|

|

|

|

|

|

Otherwise you'll just go on seeing the one name:

Otherwise you'll just go on seeing the one name:

|

There are better things to do in a ski resort than nerding about with wax and irons of an evening.

Get the local skishop to do it.

|

|

|

|

|

|

Poster: A snowHead

|

Where should the 0.5 degrees start from? That is a tiny angle, and if it starts say 1cm in from the edge of the ski, by the time you get to the metal edge it will be an almost invisible gap.

Also, how would you steer a ski whose edges didn't touch the snow? Unless there was enough speed to always be on one edge or the other, wouldn't it be wobbly?

I am at home now; no ski shop here

|

|

|

|

|

|

Obviously A snowHead isn't a real person

Obviously A snowHead isn't a real person

|

The angle is really only within the metal edge, it doesn't intrude onto the base material generally.

That half degree is relatively conservative, some will run one degree and others more than that. You'd not see radical angles generally on most broad market skis.

Steering is when you want to initiate the turn rather than the ski dictating to you. Run with no angle on base edge makes the edge engage all the time, you don't need that when going straight. As you start to roll the ski over it then starts to initiate a carve based on the ski shape along the edge from tip to waist to tail.

If you think about that interaction, you don't want both edges doing the same thing but in opposite directions while you want to go straight. It's a bit like a car when you take your hands off the steering wheel, the geometry will mostly cause it to run straight with no input.

|

|

|

|

|

|

Well, the person's real but it's just a made up name, see?

Well, the person's real but it's just a made up name, see?

|

@peter_h, When @ski3, is referring to the 0.5-1.5 degrees, I believe that they are talking about the bevel shown in all pics apart from top left.

Picture referenced from https://www.beasttuning.com/How-to-Tune-Ski-Edges-s/48.htm

But you see in all 4 cases, the ski base is flat ( not concave ).

|

|

|

|

|

|

You need to Login to know who's really who.

You need to Login to know who's really who.

|

The metal edge is about 2mm wide so a 0.5 degree slope on that would be 0.02mm (0.001") which is negligible.

There must be something else going on.

Indeed I see the base should be flat but perhaps there are manufacturing tolerances? Or is a ski machined flat during manufacture? These skis are pretty flat on nearly the whole portion in contact with the slope.

That's an interesting article there. That mentions 1-3 degrees. I will check what I have... The funny thing is that I've taken these skis to various shops over time and nobody said anything. The edges are still sharp.

Last edited by You need to Login to know who's really who. on Wed 28-11-18 9:13; edited 1 time in total

|

|

|

|

|

|

Anyway, snowHeads is much more fun if you do.

Anyway, snowHeads is much more fun if you do.

|

|

OP update - I ended up buying a couple of Zardoz Notwax pucks as a stopgap measure for skiing the first day - I also picked up a portable edge file. Will leave skis in shop for wax / service at the end of day it required. Will look at self service for 2019/2020 season once I have done a Piste Office course dureing off season. Thanks all for your input.

|

|

|

|

|

|

You'll need to Register first of course.

You'll need to Register first of course.

|

|

|

|

|

|

I have just looked at them closely.

The bottoms of the metal edges are flat, as close as I can measure it. Bear in mind that 1 degree, over the 2mm width, would need a microscope to see.

The sides have a slope of about 2 degrees.

Without question, this is how Salomon made them.

|

|

|

|

|

|

|

|

@peter_h, you don't need a microscope to see/measure the base edge angle if you apply a bit of basic geometry.

Assuming that your ski base is flat then a straight edge held flat across the base edge angle with be 1mm off the ski base at a position 60mm across the base from the edge. This is how all base edge angle guides work, ie a 1mm thick shim positioned 60mm from the edge will create a 1 degree down angle when the alu-oxide stone or possibly a diamond file is inserted.

|

|

|

|

|

|

You'll get to see more forums and be part of the best ski club on the net.

You'll get to see more forums and be part of the best ski club on the net.

|

|

@peter_h, find a true flat edge (engineers edge or a metal ruler etc) hold it against the base at right angles to the ski and sight it against a light source, you should see a chink of light between the metal ski edge and the straight edge. As you said it is a very small , but it is just enough to require a small movement in the legs to get the sharp edge to engage when you want it to rather than at random.

|

|

|

|

|

|

|

|

OK... I can get the tools to flatten these skis, but the bigger Q is: would Salomon have been selling 700 quid (that's at Snow & Rock Brighton; I bought these mail order from a shop in Scotland for half that) skis, set up like this?

In the above photo, the LH metal edge has a gap below the ruler. I can measure it with a feeler gauge if needed. But the RH edge has no gap.

|

|

|

|

|

|

snowHeads are a friendly bunch.

snowHeads are a friendly bunch.

|

You say they are still sharp, yet in 3 years / 10 trips they have never been waxed? Have the edges been sharpened, cos they can't possibly be sharp unless you have only ever skied fluffy powder!!

Get them to a proper ski service person. Yes they can come out of the factory with bases that aren't flat. You don't do a base grind with tools you can buy.

|

|

|

|

|

|

And love to help out and answer questions and of course, read each other's snow reports.

And love to help out and answer questions and of course, read each other's snow reports.

|

Its a bit of fun and an enjoyable past time when done listening to music and a beer at hand... !!

I got the iron off local free adds .. all the other stuff are easy to get hold of..

I learnt from youtube...... loads of tutorials there.

I now get them done in resort to match the weather conditions at the time

|

|

|

|

|

|

|

|

The net effect is that you've got a geometry on them that will give quite unpredictable response to you the skier. Even from left to right they appear to differ.

How that's come about is anyone's guess.

It's relatively easy to correct though. It's going to be far easier to have them base ground and edges reset to normal spec for those skis. It'll give you a decent baseline on which to proceed.

|

|

|

|

|

|

You know it makes sense.

|

Is there someone in the Brighton area who can do this?

I have the iron and the waxing kit.

The edges are really sharp. I am not a hard core skier; I only started 3 years ago and do just greens and blues, 1 or 2 reds with powder on them

|

|

|

|

|

|

Otherwise you'll just go on seeing the one name:

Otherwise you'll just go on seeing the one name:

|

|

|

|

Poster: A snowHead

|

|

|

|

Obviously A snowHead isn't a real person

Obviously A snowHead isn't a real person

|

Watching that guy in their own video run a pretty course file down the side edge of ski like he did I wouldn't touch 'em with a barge pole!

|

|

|

|

|

|

Well, the person's real but it's just a made up name, see?

Well, the person's real but it's just a made up name, see?

|

If you nare saying the base is slighty convex at the tip and tail i.e. "hulled" base high then this may be a design decision - certainly I remember some Fischer freeride skis that were marketed with a tip like that for better powder performance.

The effect would be to reduce tip and tail catchiness and require slightly more positive tipping to engage the edge in those areas. Edge high or railed is to be avoided for the reasons given above.

|

|

|

|

|

|

You need to Login to know who's really who.

You need to Login to know who's really who.

|

It is concave (i.e. it "caves in"  ) at the two ends. ) at the two ends.

The above photo shows the effect but only just visible.

Whether the two ends (the last 20-30cm of the ski) do much in practice I don't know.

When skis are manufactured, do they grind the underside and then bend them, or do they bend them first and then grind the underside? If the former, that would explain the slight concave because no way will it be flat after it is bent longitudionally.

There were not cheap skis...

|

|

|

|

|

|

Anyway, snowHeads is much more fun if you do.

Anyway, snowHeads is much more fun if you do.

|

I would like to learn how to mount bindings even try myself but templates are not available for some bindings

|

|

|

|

|

|

You'll need to Register first of course.

You'll need to Register first of course.

|

They are formed in a press. It's not uncommon to have some slight concavity on new skis from the curing process. I've had a couple of pairs like that. It doesn't really cause an issue at tip or tail, but concavity on the central flat section could cause a suction effect on wet snow (e.g

spring conditions) and a base grind will sort that out.

|

|

|

|

|

|

|

|

@peter_h, so what you are showing is a gap in the middle under the rule? Doesn't look like much.

Skis obviously have manufacturing tolerances and then various degrees of QC in the factory. If you measure everything with micrometers etc then you are likely to be disappointed with the outcome. I know @spyderjon will tell you that there are some brands that are shocking for the state the skis leave the factory in and accordingly the prep he has to do before handing them to a customer. Your real remedies are to buy them from a shop that knows what they are doing and will prepare them prior to you taking delivery or skiing them and seeing if the slight concavity is a real issue.

(I have bought many pairs of skis both new and used and have never taken a true bar to them to fret about base height and they have been fine).

You say you bought them from S+R - if you haven't skied them take them in and make them do a base grind if you are really worried - warning though most people will tell you base grinds are last resort because they reduce the life of your skis.

|

|

|

|

|

|

|

|

|

|

|

You'll get to see more forums and be part of the best ski club on the net.

You'll get to see more forums and be part of the best ski club on the net.

|

|

@spyderjon thank you. I didn't buy from you, ending with bindings and skis separately. Do you mind providing the mounting service for such customers? I would like qk inserts as well. Cheers

|

|

|

|

|

|

|

|

Dave - I bought them mail order from a shop in Scotland (see above). I merely mentioned they were £700 at S+R so "not cheap and dirty skis".

I have just spoken to a ski tuning guy and he will take a look at them. He told me this concave stuff is normal and is ok so long as the main middle bit of the ski is flat. He did however say that a lack of a slope on the underside of the metal edges will make it hard to ski with it, so that needs doing.

|

|

|

|

|

|

|

|